#BERLIN — Blue Origin flew six people, including a pair of repeat customers and a science communicator, on the latest New #Shepard suborbital spaceflight mission Nov. 22.

The New Shepard vehicle lifted off from Blue Origin’s Launch Site One in West Texas at 10:30 a.m. Eastern. The flight lifted off on schedule without any of the countdown holds common during previous flights.

The New Shepard capsule R.S.S. First Step, making its 11th flight, landed about 10 minutes after liftoff, two and a half minutes after the booster landed, completing its 12th flight. The capsule reached a peak altitude of 107 kilometers above sea level, Blue Origin reported after the flight.

The six-person crew of NS-28 included two people who previously flew on New Shepard. Marc and Sharon Hagle, husband and wife, flew together on the NS-20 mission in March 2022, the fourth crewed flight of the vehicle.

Also on board was Emily Calandrelli, an author, television show host and online science communicator. In a social media post, she said she would become the 100th woman to go to space. That number, however, includes nine women who have flown on Virgin Galactic suborbital spaceflights that passed the 50-mile (80.5-kilometer) altitude used by U.S. government agencies for awarding astronaut wings but fell short of the 100-kilometer Kármán Line used by Blue Origin as the demarcation of space. Blue Origin, in its webcast of the launch, did not mention that milestone when discussing Calandrelli.

The other three people on NS-28 were Austin Litteral, who works in risk management in the financial industry and won his seat in a contest by an online shopping platform; James (J.D.) Russell, a technology entrepreneur; and Henry (Hank) Wolfond, chairman and chief executive of Canadian investment firm Bayshore Capital.

NS-28 with the ninth crewed flight by New Shepard and the third this year. It was also the second flight in one month after the uncrewed NS-27 flight Oct. 23. That mission was the first flight of a new crew capsule and booster that Blue Origin plans to use for future crew flights to provide “expanded flight capacity to better meet growing customer demand,” the company said at the time.

View 465 times

#SpaceX launches giant Starship rocket, but passes up catching it with mechanical arms.Unlike last month’s success, the booster was directed to a splashdown in the Gulf of Mexico. The catch was called off just four minutes into the test flight from Texas for unspecified reasons, and the booster hit the water three minutes later.

Not all of the criteria for a booster catch was met and so the flight director did not command the booster to return to the launch site, said SpaceX spokesman Dan Huot. He did not specifying what went wrong.

At the same time, the empty spacecraft launched from Texas atop Starship soared across the Gulf of Mexico on a near loop around the world similar to October’s test flight. Skimming space, the shiny retro-looking craft targeted the Indian Ocean for a controlled but destructive end to the hourlong demo.

It was the latest test for the world’s biggest and most powerful rocket that SpaceX and NASA hope to use to get astronauts back on the moon and eventually Mars.

SpaceX kept the same flight path as last time, but changed some steps along the way as well as the time of day. Starship blasted off in late afternoon instead of early morning to ensure daylight halfway around the world for observing the spacecraft’s descent.

Among the new objectives: igniting one of the spacecraft’s engines in space, which would be necessary when returning from orbit. There were also thermal protection experiments aboard the spacecraft, with some areas stripped of heat tiles to see whether catch mechanisms might work there on future flights. Even more upgrades are planned for the next test flight.

Donald Trump flew in for the launch in the latest sign of a deepening bond between the president-elect and Elon Musk, SpaceX's founder and CEO.

Top science and technology headlines, all in one place

SpaceX wants to eventually return and reuse the entire 400-foot (121-meter) Starship. Full-scale recycling would drive down the cost of hauling cargo and people to the moon and Mars, while speeding things up. The recycling of SpaceX’s Falcon rockets flying out of Florida and California has already saved the company time and money.

NASA is paying SpaceX more than $4 billion to land astronauts on the moon via Starship on back-to-back missions later this decade. Musk envisions launching a fleet of Starships to build a city one day on Mars.

This was the sixth launch of a fully assembled Starship since 2023. The first three ended up exploding.

View 465 times

#Satellite operator Spire Global is selling its commercial ship-tracking business to an analytics provider to invest in other data markets and its hosted payload services.

Vienna, Virginia-based Spire Global said Nov. 13 it has reached a $241 million deal to sell maritime customer contracts to Kpler of Belgium, which would also get exclusive rights to sell ship-tracking data from the operator’s satellites to commercial entities and governments worldwide.

Spire Global would retain its satellites, technology, and other infrastructure following the transaction, which includes $7.5 million for services over 12 months, as well as its current maritime customers in the U.S. government.

The proceeds would help Spire Global pay off all its outstanding debt, around $100 million worth, giving the company more financial firepower for near-term growth opportunities across its weather, aviation, radio frequency geolocation, and space services markets.

“We are now even better equipped with the resources, technology and experience to serve governments and commercial clients to fulfill their missions,” Spire Global CEO Peter Platzer said in a statement.

#Kpler CEO Mark Cunningham said the acquisition would materially improve its maritime analytics capabilities, which use space and terrestrial sensors to track #AIS — Automatic Identification Systems — transponders required on all passenger ships and most ocean-going vessels above a certain tonnage.

View 475 times

VOSTOCHNY #SPACEPORT, November 5. A Soyuz-2.1b #rocket blasted off from Vostochny #Spaceport carrying a pair of Ionosphere-M heliogeophysical satellites and 53 other Russian and foreign satellites, according to a #TASS reporter.

About nine and a half minutes after liftoff, the rocket’s tip and the Fregat upper stage will separate from the third stage. The Ionosphere-M satellites, which are the main payload, are set to be put into a sun-synchronous orbit within an hour.

View 506 times

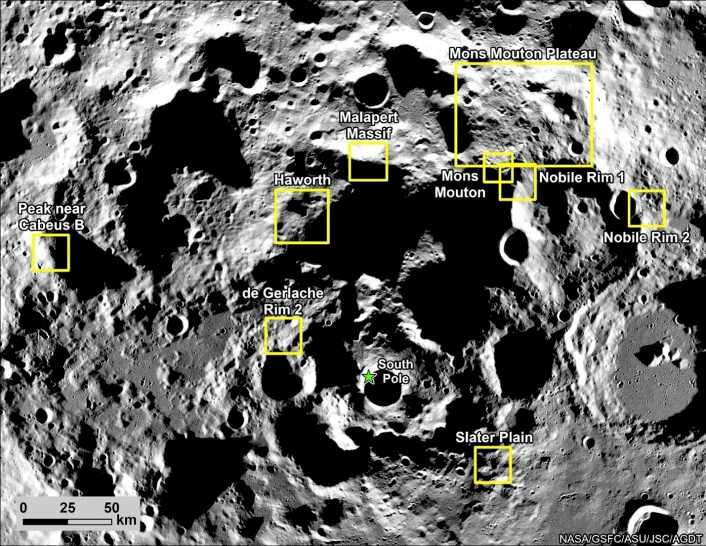

#WASHINGTON — #NASA has updated a list of candidate landing sites near the south pole of the moon for the Artemis 3 mission, taking into account surface conditions and capabilities of SpaceX’s Starship lander.

NASA announced Oct. 28 that it had updated the locations in the lunar south pole region it was considering for the Artemis 3 mission. The agency had released a list of 13 candidate landing locations there in August 2022.

The nine locations include some of the same regions of the earlier list as well as new locations. All are clustered near the lunar south pole, a region of science and exploration interest because of the potential of water ice deposits in permanently shadowed craters.

The analysis required a “multi-variable” analysis, said Tamra George of NASA’s Johnson Space Center during an Oct. 28 presentation about the landing sites at the annual meeting of the Lunar Exploration Analysis Group (LEAG). “Our number one priority is that safe landing and safe return of our astronauts, and with doing that, getting some amazing science,” she said.

That required accounting for a wide range of factors. They include surface conditions at the landing site within the capabilities of Starship as well as lighting conditions and visibility of the Earth for direct-to-Earth #communications. That can be “tricky,” she said, particularly during winter, when it can be difficult to find both acceptable lighting and #Earth visibility conditions for the projected six-day surface stay.

View 495 times

#WASHINGTON — #NASA Administrator Bill Nelson said he is concerned about reports that Elon Musk, chief executive of SpaceX, has had discussions with Russian President Vladimir Putin.

Nelson’s comments, made at Semafor’s World Economy Summit Oct. 25, represent his strongest public criticism to date of the owner of the company that NASA relies upon for transporting crews to the International Space Station and for launching key missions.

In an on-stage interview at the summit, Nelson was asked about a Wall Street Journal article that stated that Musk has had a regular series of conversations with Putin over the last two years, starting after Putin embarked on a full-scale invasion of Ukraine. The article said it confirmed those discussions with current and former American, European and Russian officials.

According to the article, the discussions between Musk and Putin included a request by Putin that SpaceX not activate its Starlink service over Taiwan, as Russia sought to win support from China. SpaceX does not provide Starlink service in Taiwan, but it is unclear if that request was a factor

“I don’t know that that story is true,” Nelson said at the conference. “I think it should be investigated. If the story is true that there have been multiple conversations between Elon Musk and the president of Russia, then I think that would be concerning, particularly for NASA, for the Department of Defense, for some of the intelligence agencies.”

Nelson has avoided directly criticizing Musk even after the billionaire increasingly disparaged the Biden administration and, in July, formally endorsed Donald Trump for president. Musk is now actively campaigning for Trump, holding a series of town halls in Pennsylvania, one of the key swing states in the presidential election.

Nelson has frequently noted that he does not deal directly with Musk about SpaceX but instead with Gwynne Shotwell, the president and chief operating officer of the company. Shotwell runs SpaceX on a day-to-day basis, but Musk is the chief executive and largest shareholder and drives the overall vision of the company.

View 509 times

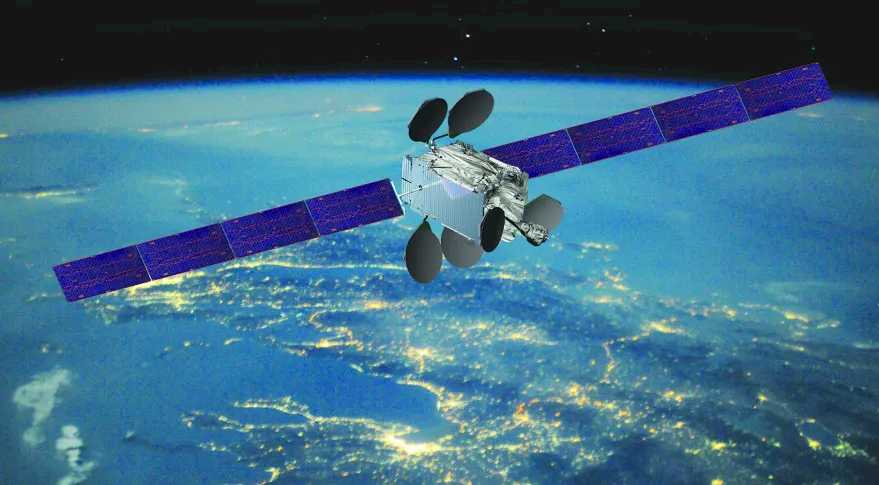

#Intelsat 33e loses power in geostationary orbit .

TAMPA, Fla. — Intelsat 33e has lost power in geostationary orbit and the satellite is no longer providing communications for customers across Europe, Africa and parts of Asia Pacific, its operator announced Oct. 19.

Intelsat said it is working with satellite maker Boeing to address the anomaly, but “believe it is unlikely that the satellite will be recoverable.” An Intelsat spokesperson said the satellite was not insured at the time of the issue.

The company said in a brief news release it is working to move customers to other satellites in Intelsat’s fleet or spacecraft operated by third parties.

Intelsat 33e launched in August 2016 and entered service in January 2017 at 60 degrees East, about three months later than planned following an issue with its primary thruster.

A second propulsion issue that emerged during in-orbit tests helped knock off around 3.5 years from the satellite’s initially estimated 15-year lifespan.

Intelsat 33e is the second in Intelsat’s EpicNG (next-generation) series of high-throughput satellites.

The first, Intelsat-29e, was declared a total loss in 2019 after just three years in orbit. That failure was pinned on either a meteoroid impact or a wiring flaw that led to an electrostatic discharge following heightened solar weather activity.

View 531 times

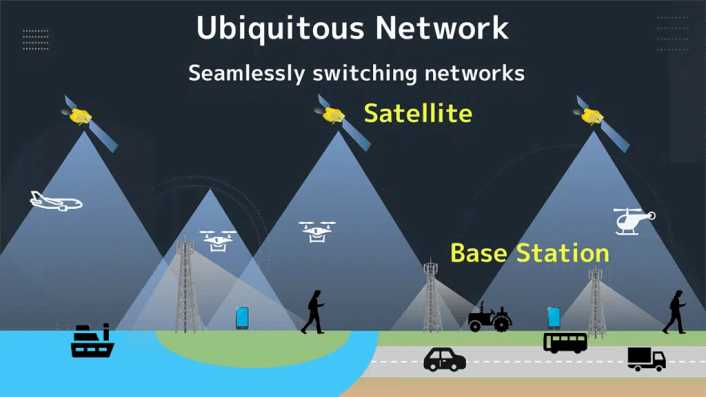

Efforts to standardize #satellite and terrestrial #communications are moving beyond narrowband capabilities toward a universal broadband terminal for seamless, global connectivity.

#Geostationary operator Intelsat recently partnered with Softbank, a Japanese internet conglomerate, to essentially integrate satellites with the roaming agreements cellular companies use to keep subscribers connected from country to country.

The partnership is one of the first practical steps Intelsat has taken toward 5G following years of rhetoric about the revolutionary capabilities on the horizon for truly global hybrid connectivity.

It comes a few months after 3GPP, a mobile industry consortium, approved plans to work Ku-band satellite spectrum into a future update for the 5G standards used by smartphones and other mass-market devices.

The standardization work builds upon the integration of space-based narrowband connectivity with 5G, which satellite operators such as Viasat are leveraging to provide basic messaging services to certain smartphones coming out later this year.

View 514 times

The U.S. Space Force announced that its secretive X-37B spaceplane will execute a series of maneuvers to change its orbit and jettison components.

The reusable #spacecraft, which has been in orbit since December 28, 2023, will perform aerobraking maneuvers to alter its trajectory around Earth, the Space Force said Oct. 10. This technique involves making multiple passes through the planet’s upper atmosphere, using atmospheric drag to modify the vehicle’s orbit while conserving fuel.

These maneuvers also are intended to showcase responsible space operations, the Space Force said. The aerobraking enables the spaceplane to change orbits and comply with space debris mitigation rules by safely discarding the service module.

The X-37B, manufactured by Boeing, is jointly operated by the U.S. Space Force and the Air Force Rapid Capabilities Office. Since its launch aboard a SpaceX Falcon Heavy rocket from NASA’s Kennedy Space Center in Florida, the spaceplane has been conducting radiation effect experiments and testing space domain awareness technologies in a highly elliptical orbit.

Experts note that the X-37B’s current mission, its seventh to date, has taken on increased significance in light of recent developments in space capabilities by other nations. The launch of the X-37B came just two weeks after China sent its own Shenlong spaceplane into orbit, fueling speculation about both countries’ intentions.

In orbit for extended periods

The X-37B, capable of operating at altitudes between 150 to 500 miles above Earth, has previously demonstrated the ability to remain in orbit for extended periods, with missions lasting over 900 days. This longevity allows for prolonged studies on the effects of space radiation and other environmental factors on various materials and technologies.

“There is no other space platform as capable, flexible and maneuverable as the X-37B.” Michelle Parker, vice president of Boeing’s Space Mission Systems, said in a statement.

After completing its aerobraking maneuvers, the X-37B will resume its testing and experimentation objectives. Once these are accomplished, the vehicle will de-orbit and return to Earth, utilizing its autonomous landing system to touch down horizontally like a conventional aircraft.

The Space Force has not disclosed the expected duration of the current mission.

“This first-of-a kind maneuver from the X-37B is an incredibly important milestone for the United States Space Force as we seek to expand our aptitude and ability to perform in this challenging domain,” said Gen. Chance Saltzman, chief of space operations.

View 532 times

#MILAN — #SpaceX launched its fifth Starship vehicle Oct. 13, successfully making an unprecedented “catch” of its Super Heavy booster back at the launch site.

The Starship/Super Heavy vehicle lifted off from the company’s Starbase site at Boca Chica, Texas, at 8:25 a.m. Eastern on a mission called Flight 5 by SpaceX.

The main upgrade for this test was an attempt by SpaceX to recover the Super Heavy booster by having it come back to the launch site, where it would be cradled by two mechanical arms, sometimes called “chopsticks,” attached to the launch tower it lifted off from. That required the booster to perform precise boostback and landing burns to guide the stage back to the launch pad.

The Super Heavy booster, known as Booster 12, achieved that feat. The booster descended over the pad and the two arms closed around the top of the booster, just below the grid fins, about seven minutes after liftoff, achieving the desired catch of the booster.

Achieving the launch pad return and landing is critical to SpaceX’s long-term ambitions for rapid reflight of the vehicle. In the company’s vision, the landed booster could be rapidly turned around on the pad, with a Starship attached for its next flight within days or even hours.

The success of the catch appeared to take even company leaders by surprise. “I don’t know what to say!” posted Gwynne Shotwell, president and chief operating officer of the company, on social media, attaching a video of the landing.

Before the launch, though, Bill Gerstenmaier, vice president of build and flight reliability, was optimistic about the catch attempt. “We landed with half a centimeter accuracy in the ocean” on the previous flight, he said at an Oct. 9 meeting of the National Academies’ Committee on Biological and Physical Sciences in Space, “so we think we have a reasonable chance to go back to the tower.”

The Starship vehicle, Ship 30, flew on a suborbital trajectory similar to the previous flight in June, reaching a peak altitude of 212 kilometers. The vehicle appeared to survive reentry in better condition than on that previous flight; SpaceX noted it made changes to Starship’s heatshield. The vehicle made a powered ocean “landing” in the Indian Ocean nearly 66 minutes after liftoff, with the vehicle, not intended to be recovered, exploding several seconds after splashing down.

“Ship landed precisely on target!” Elon Musk, chief executive of SpaceX, posted minutes after the landing. “Second of the two objectives achieved.”

Last-minute license

The launch took place less than 24 hours after the Federal Aviation Administration issued a revised launch license for the mission, the subject of controversy over the last month after SpaceX complained it had been informed by the FAA that the updated license would not be ready until late November.

The license required revisions to an environmental assessment because of changes in the flight profile, including a larger area where the interstage ring, also called a forward heat shield in FAA documents, might be dropped in the Gulf of Mexico as well as a sonic boom analysis for the returning Super Heavy booster.

That environmental analysis, signed and published a few hours before the license was granted, concluded “no structural damage or significant impacts to third-party structures is anticipated” from sonic booms. “No adverse impacts to biological resources in the Gulf of Mexico are anticipated as a result of the proposed change to the forward heat shield landing location,” it stated.

The analysis, though, does include several conditions related to the overall effects of Starship launches at Boca Chica, including “field experiments to determine the extent of the gravel plume impact area” caused by Starship launches, which would support any measures to protect bird nests in the surrounding wildlife preserve, as well as monitor other impacts of the launches on birds there. The company must also provide an annual certification “attesting to SpaceX’s compliance with all applicable environmental laws, regulations, permits, or other authorizations” relating to launches at Starbase.

SpaceX compliance to those laws has also been a topic of controversy regarding the permitting of a water deluge system at the pad, which resulted in the company agreeing to a nearly $150,000 fine from the Environmental Protection Agency for operating the deluge system with an EPA permit. The company noted it did have a permit from Texas regulators.

The revised license requires SpaceX to provide the company with the state and, when completed, EPA permits for the deluge system and “to send the FAA copies of all monitoring data within 45 days of sampling the use of its deluge system.”

The license does allow SpaceX to conduct at least one more launch, called Flight 6, using the same profile without obtaining another authorization from the FAA. “The SpaceX Starship/Super Heavy Flight 5 license authorization also includes FAA approval of the Flight 6 mission profile,” the agency stated. “The FAA determined the changes requested by SpaceX for Flight 6 are within the scope of what has been previously analyzed.” The agency didn’t state what those changes were.

View 515 times

Space news on Umojja.com